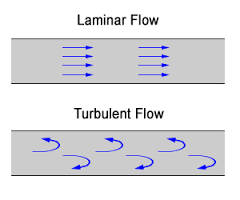

The mixing of low viscosity additives into very high viscosity bulk (μ a/μ b ≪ 1/1000) is of particular industrial significance, for example blending of additives such as mineral oil into polymer melts such as polystyrene (Streiff and Schneider, 1983). (2016), so this paper focusses on the laminar flow regime.

The findings from the turbulent and transitional flow regimes have previously been published in Simpson et al. The objectives of this work were to investigate the effects of dosing additives both more and less viscous than the bulk on blending performance in the laminar flow regime using different scales of Chemineer Kenics KM static mixer. The increase in L mix/D when μ a/μ b < 1 (dilution of viscous bulk) was always due to the presence of single or multiple strands of low viscosity additive (striations) which broke through L mix/D = 54 under some conditions. The laminar flow L mix/D results demonstrated a strong influence of μ a/μ b outside a fairly narrow range around μ a/μ b = 1.

In the laminar flow regime ( Re mixer < 10), the effect of additive and bulk viscosity on L mix/D was characterised using the viscosity ratio μ a/μ b as opposed to the modified Reynolds number, Re*. L mix/D reproducibility was found to be within ☑.5 (☑ Kenics element). L mix/D measurements were made by visually observing the dispersion and blending of a coloured additive stream using both DN20 and DN50 Chemineer Kenics KM of 24 and 36 1.5 pitch ratio elements, respectively. In this paper, experimental results on the determination of mixing length ( L mix/D) when dosing additives both more and less viscous than the bulk flow using the Chemineer Kenics KM are described. However, published information describing the effect of additive ( μ a) and bulk ( μ b) viscosity differences on inline blending performance is sparse. The use of continuous, inline systems to dose, mix, sample and control injected additives is common in the process industries.

0 kommentar(er)

0 kommentar(er)